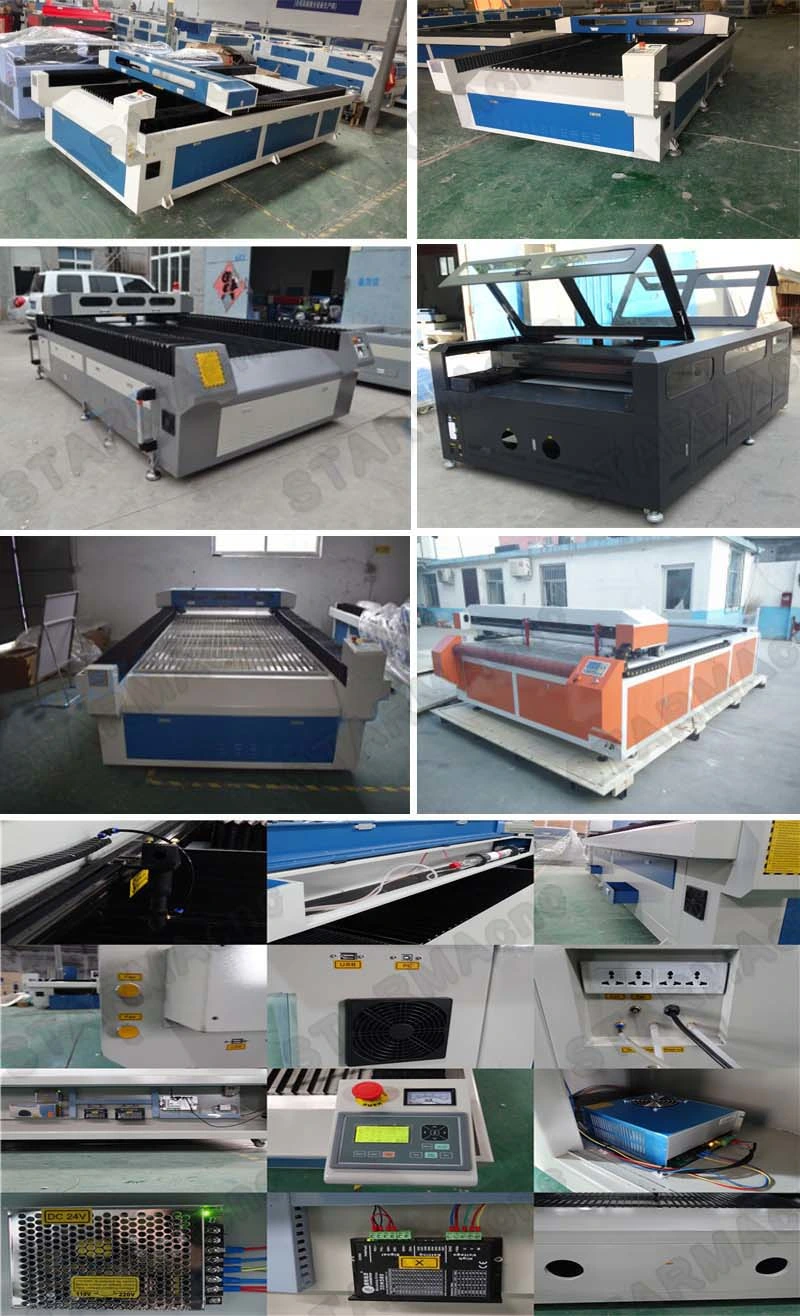

| Model | SM-B1325 | ||||

| Engraving Area (mm)W*L | 500*300 | 900*600 | 1300*900 | 1600*1000 | 1300*2500 |

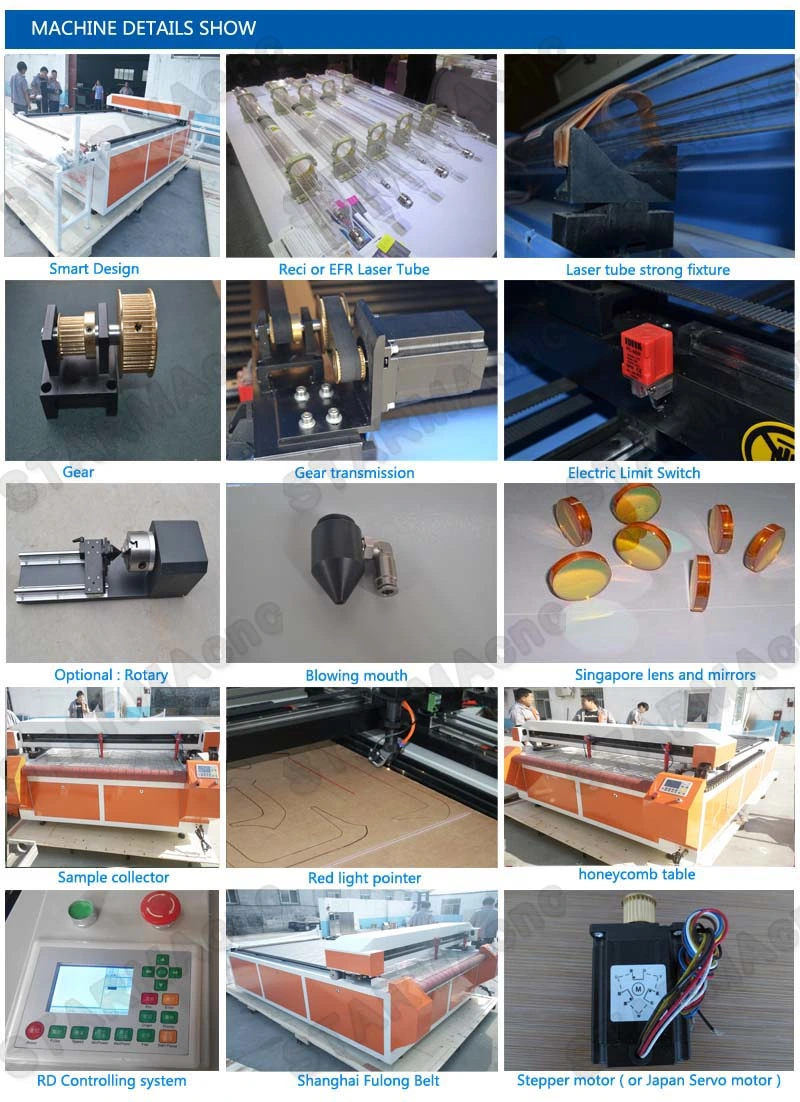

| Laser tube power | 40W 60W 75W 90W 100W 130W 150W 260w | ||||

| Laser Type | CO2 sealed laser tube RECI brand | ||||

| Engraving Speed | 0-64000mm/min | ||||

| Cutting Speed | 0-36000mm/min | ||||

| Resetting positioning accuracy | ≤±0.01mm | ||||

| Laser Output | 1-100%software setting | ||||

| Cooling mode | Circulating-water-cooling and protection system | ||||

| Machine control and drive | Speedy DSP controlling, stepper motor | ||||

| Cutting Platform | knife-strip platform | ||||

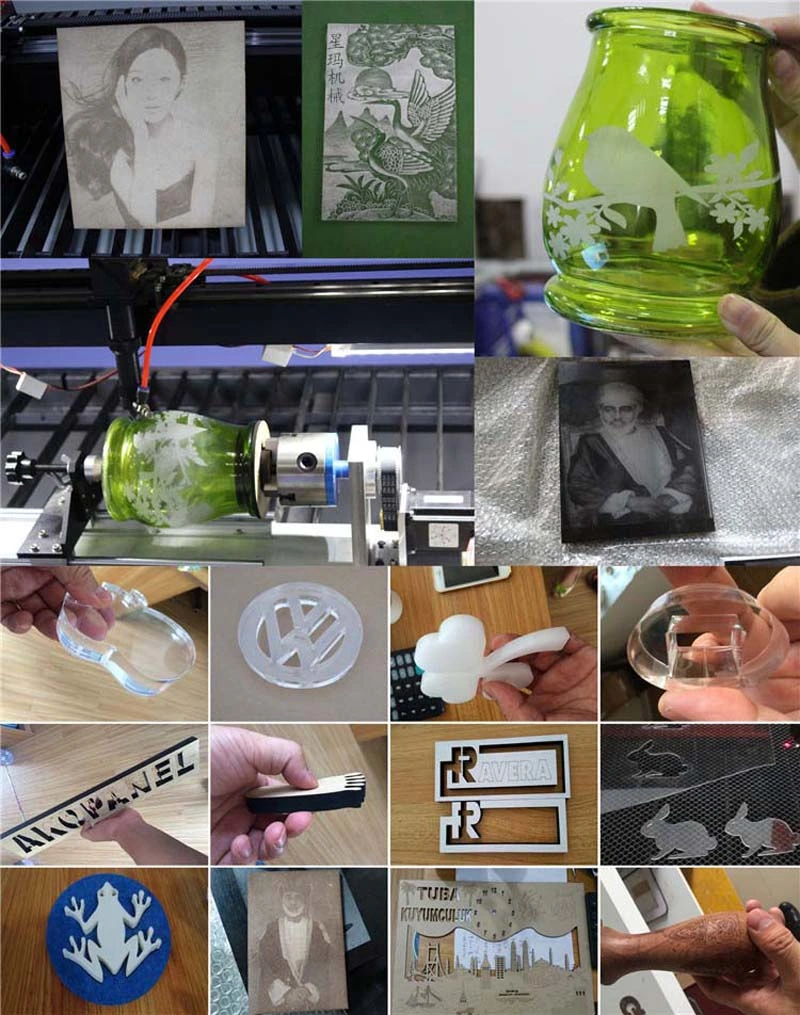

| Min. shaping character | Character 2.0mm×2.0mm,English1.0mm×1.0mm | ||||

| Power Supply | AC220V 50HZ | ||||

| Operating system | DSP off-line control system | ||||

| Dictate format | *.plt,*.dst,*.dxf,*.bmp,*.dwg,*.al,*las etc. | ||||

| Operating Temperature | 5°C-40°C | ||||

| Operating Humidity | 5-95%(Free of Condensed Water) | ||||

| Compatible Software | CorelDraw ,AutoCAD transmit directly | ||||

| Optional Spare Parts | Rotary system, Industrial Chiller, Infrared Locating System,Laser Tube, Up-down table | ||||

| Consumable Spare Parts | Laser Tube and laser lens | ||||

| Other machine size | 600*400mm,1300*1000mm,1200*1200mm, 1300*1800mm,1600*1200mm,1600*2000mm, 1600*3000mm,1800*1000mm and other customized | ||||

Samples

Package

Jinan CNC Wood Laser Cutting Machine Price

Our other laser cutting machine

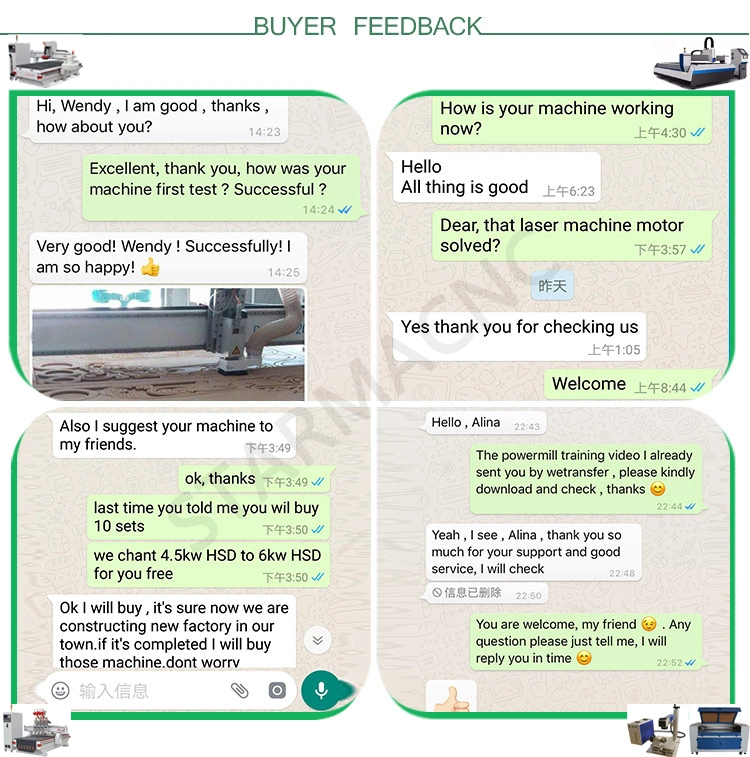

Our Services

1.24 hours technical support by mail or calling.

2. Friendly English version manual and operation video.

3. Machine will be test ok before packing

Our Company

Jinan STARMA Machinery Equipment Co, Ltd Located in jinan district China, it is a professional manufacturer devoted to laser processing, develop laser engraving machine, laser cutting machine of several series. Providing you perfect laser processing solution.

You can choose proper processing area and laser power to carve and cut non-metal material. We are well praise with our strength function. Low price, good steadily

and wonderful after sale service.

Please let us know following informations:

1. What materials you want to cut?

2. What is the mostly used thickness and what is the maximum thickness?

3. What is the MAX. dimension of your materials?

4. After cut, what will be the metal used for? (application)

5. Are you an end user or reseller?

According to your above information, we'll recommend the most suitable machine to you.

Machine Working Video:

https://starmacnc.en.made-in-china.com

https://starmacnc.en.made-in-china.com

https://starmacnc.en.made-in-china.com