Product Description

ATF-3015-F fiber laser cutting machine is Alpha's new design, which is designed by European designers. It is more in line with modern aesthetics.

The main parts of the machine are all world famous brand, such as the Japan Fuji drive motor, the German Vastun square rail and helical rack, the Taiwan TBI ballscrew on Z axis, Switzerland Raytools laser head, France Schneider and American Honeywell Low Voltage Electric parts.

It has many uses and can save the space of more than 50%, which effectively improve productivity.

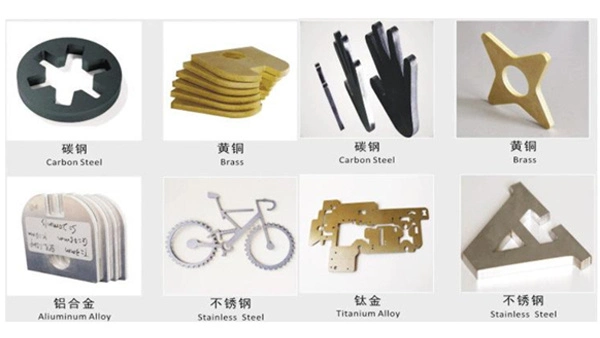

Application Material

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting like stainless steel sheet, mild steel plate, carbon steel sheet, alloy steel plate, spring steel sheet, iron plate, galvanized iron, galvanized sheet, aluminum plate, copper sheet, brass sheet, bronze plate, gold plate, silver plate, titanium plate, metal sheet, metal plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture billboard, advertising, signs, signage, metal letters, LED letters, kitchen ware, advertising letters, sheet metal processing, metals components and parts, ironware, chassis, racks & cabinets processing, metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, glasses frame, electronic parts, nameplates, refrigeration machinery, agricultural machinery, food machinery, kitchen stainless steel countertops, aerospace, railroad locomotive, auto parts manufacturing, car body processing, medical equipment, smart home, home appliances, kitchen equipment, fitness equipment, machinery manufacturing, sheet metal processing. etc.

Working Area | 3000*1500mm |

X axis working area | 3,000mm |

Y axis working area | 1,500mm |

Laser Power | 2000W/3000W for option |

Positioning accuracy | ±0.03mm |

Repeatability positioning accuracy | ±0.02mm |

XY Axis Maximum Acceleration | 1g |

XY Axis Max. speed | 80m/min |

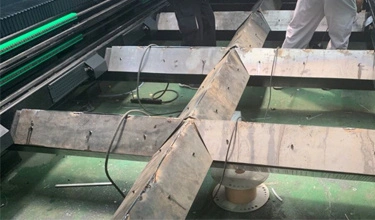

Working Table | Serrate working platform |

XY Axis Transmission system | German helical rack and pinion |

Z axis Transmission system | Taiwan TBI ballscrew |

Cooling System | Industry water chiller |

Power Supply Rated Voltage | 3-phase 380V/50Hz or Custom made |

Machine Weight | 4,000KG |

Dimension | 2250*4200*2100mm |

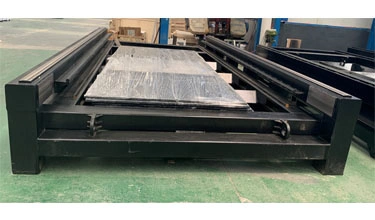

Heavy duty steel welded machine frame

Our machine frame is heavy duty, steel welded and we have the aging vibration process, annealed process. So the machine will not get deformed for long time use.

Here is the process of how we make our machine frame:

Using the thick steel pipe to weld the machine frame→ Annealing process→ Rough machining→ Vibratory Stress Relief → Fine machining

resistance, oxidation resistance and low density, which can greatly improve the processing speed.

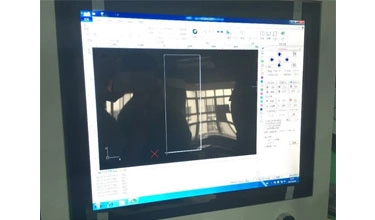

CypCut Controller

Functional possibility:

1.Supports three levels of perforation, segmentation or progressive combination

2.Support communication control of most mainstream lasers in the market

3.Supports basic processes such as flying cutting, leapfrog, compensation, threading, micro-connection, pre-perforation, film cutting

4.Supports capacitor patrol edge, photoelectric, electric focusing, double table, automatic cutting tube cutting, power-off memory and other advanced functions

5.Advanced technology such as cooling point, sharp corner cutting, release angle, etc.

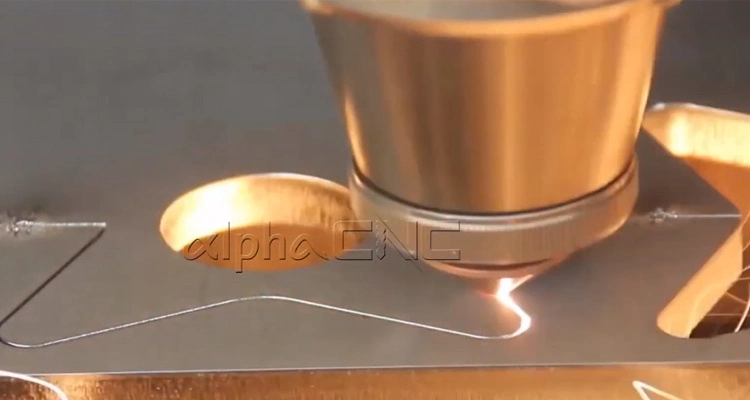

Switzerland Raytools laser head

Swiss RAYTOOLS introduces an autofocus fiber cutting head. The product has a built-in motor drive unit that automatically changes

the position by driving the focusing mirror through a linear mechanism. The user can continuously adjust the focus through the program to complete the rapid perforation of the thick plate and automatically cut the plates of different thicknesses and materials. The product is equipped with a composite lens unit to integrate the beam, and the optical and water-cooled design is

optimized so that the laser head can work stably for a long time at high power.

electro-optical conversion efficiency, good beam quality, high energy density, wide modulation frequency, high reliability, long

life and maintenance-free operation. And so on, can be widely used in welding, precision cutting, cladding, surface treatment, 3D printing and other fields. Its fiber output features make it easier to integrate with robots into flexible manufacturing equipment to meet the needs of 3D machining.

Control Cabinet

Our Company

Our CompanyAlpha CNC Co., Ltd. was established in 2000, specializing in CNC machinery with rich experience! The company has two factories: CNC Router and Laser Machine factories and plants.

Alpha CNC is comprehensive in the production, designing, manufacturing, trading and supplying service of CNC machine, and provide high quality and good efficient CNC machines worldwide. With a strong staff team, "Brand AlphaCNC " gained success in woodworking engraving machine, advertising engraving machine, stone engraving machine, metal engraving machine, laser engraving machine and laser cutting industry equipment. The production facilities occupies China's forefront in development and expansion.

"AlphaCNC Products are widely used in the fields of advertising, furniture, gifts, decoration, packaging etc., and materials of wood, acrylic, stone, fabric, leather metal, etc."AlphaCNC "is well-known not only in China, but also in Russia, Europe, Southeast Asia, Middle East, Africa, the Americas, India and other more than 120 foreign countries.

AlphaCNC is with advanced and powerful machining capability. We have imported high precision 5 axis CNC Machining center to process the machine frame, the top milling, side milling, and side drilling will be finished in one machining center, which ensure our CNC machine is with higher precision, Moreover, the small machine parts are machined by American imported Haas ATC CNC Center.

AlphaCNC has strong technical strength. We has more than 10 engineers to develop new machines every year, and our engineers will design the machine according customer's special request. We have more than 20 after-sale service engineers to serve our customers 7*24.

ALPHACNC always adhere to the principle --- First class reputation, first-class service and excellent products.

Q1: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team viewer"online, with telephone or Skype explain.

Q2: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q3 :How can I trust your company and your products?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. The testing video and pictures will be available before delivery.

Q4.If machine have any problem after I ordered it, what could I do?

Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from phone and skype.

Q5. Can I visit your factory?

Yes! We greatly welcome customers to visit our factory!

Q6. What's your date of delivery?

For standard machine, about 15 working days; For customized machine, about 20 working day.

Q7.MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.

Related Products

Please feel free to contact us for more information!