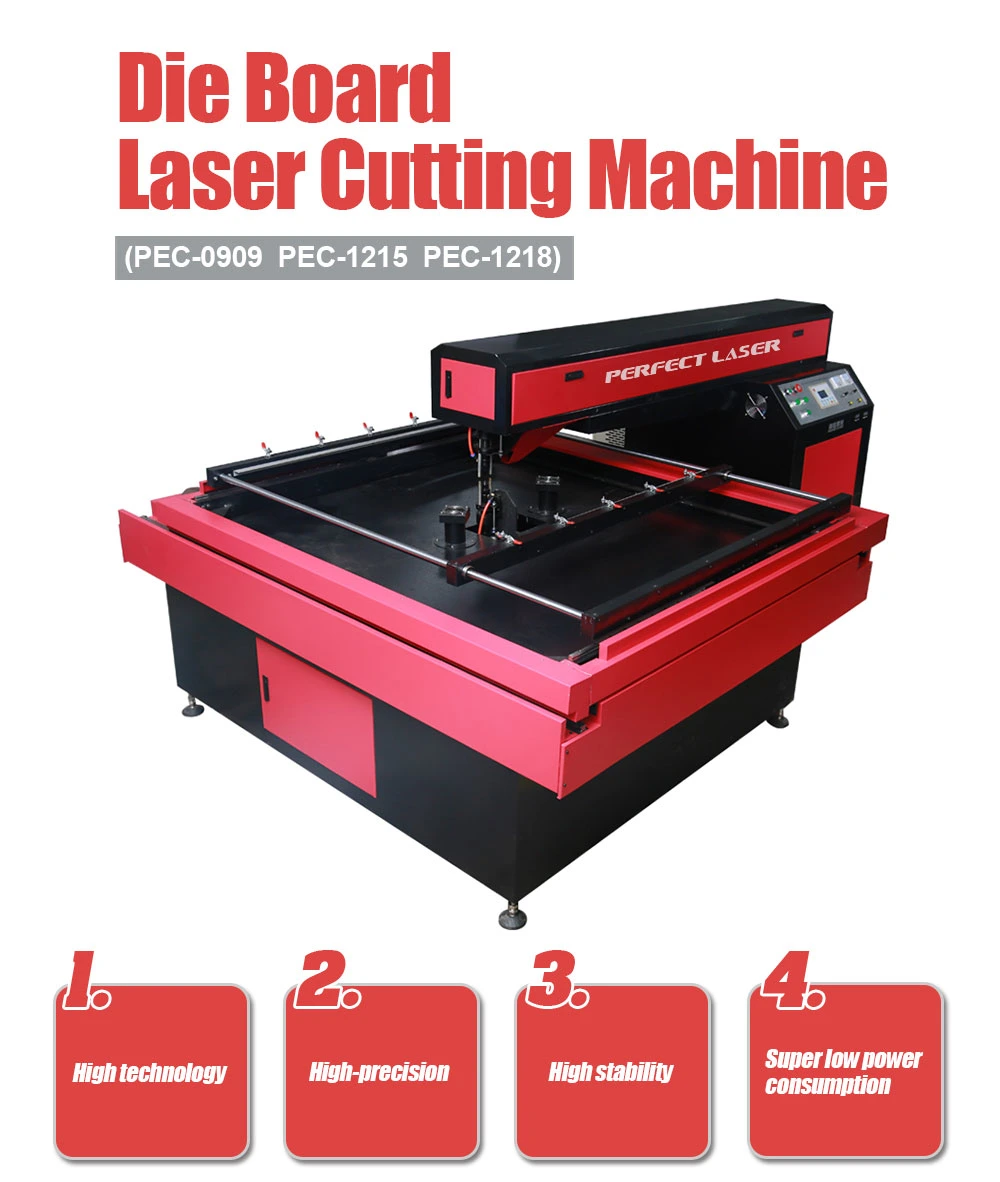

1000W Die Board Laser Cutting Machine in Metal Industry

(Model:PEC-1215)

Contact: Lydia

1. IntroductionDie Board Laser Cutter with GSI Laser PEC-1225GSI with working area 1200x2500mm, Laser Power 260W.

Compact design, High efficiency, Excellent quality, Low maintenance and Low running cost, PEC-1225GSI designed by Perfect Laser is specialized in cutting die board up to 25mm meanwhile can slightly in thin metal ( cutting metal as option).

Auto Following and Focus System designed by Perfect Laser is one of key elements to successfully cut die board. Auto Following and Focus System can automatically senses the distance from cutting head to die board being cut and then adjust the focal position to keep a good cutting quality.

PEC-1225GSI is equipped with luxury equipments, including UK 260W GSI CO2 laser tube, Tempering heat treated lathe bed, Imported ball screws and guide rail, Panasonic servo motor etc, which can guarantee the high-speed and high-precision, and make the machine long operating life.

DSP off controlling system make the machine free from computer, which convenient for you to control machine during working.

2. Applied Field

Widely used professionally to cut wood, plastic, organic glasses to make cutting dies of many fields including packages, handicrafts, advertisements etc. It can cutting thick material only once while other machine can not realized. For the common material: Wood, the maximum thickness is 25 mm.

3. Features

* Advanced LCD Touch Screen+ USB port+ DSP Offline Control

* Auto Following and Focus System

* UK 260W GSI CO2 laser tube with unparalleled beam quality, effienciency and longevity.

* Imported ball screws and guide rail, Panasonic servo motor, which can guarantee the high-speed and high-precision.

* Tempering heat treated lathe bed, which is not easy to be deformed.

* The single-head cutting and flight optical path make the adjustment of optical path more sample and reliable.

* The thickness of 15MM, 18MM, 20MM 25MM die-board can be cut arbitrary width, such as 0.45, 0.71, 1.05, 1.42 etc. Kerf uniform, consistent from top to bottom seam. Once turned on, the machine can work without waiting time.

* Low cost and no gas consumption, only consume 7.5KW/H power.

4. Machine configuration

5. Technical data

| Type | PEC-1225GSI |

| Cutting Area | 1200*2500mm |

| Laser Power | GSI 260W |

| Laser Type | Hermetic and Detached Co2 Glass Laser Tube |

| Lifetime of laser tube | more than 10000 hours |

| Cooling mode | Water cooling and protection system |

| Cutting Speed | 10 -6000mm /min |

| Repeated Position precision | +- 0.05mm |

| Maximum Cutting Depth | 25mm |

| Cutting Width | 0.35mm-0.75mm adjustable, > 0.75mm adjustable |

| Support Format | HPGL,PLT,AI,DXF etc. |

| Controlling software | DSP control system |

| Compatible software | CorelDraw, AutoCAD, Photoshop |

| Driving system | Panasonic Servo |

| Machine Power | 5KW |

| Working voltage | AC 220V(+/-10%) 50-60Hz |

| Operating temperature | 0-45 |

| Operating humidity | 5-95% |

| Whole machine size | 3350*2220*1110 mm |

6. Details

7. FAQ

Q: What's the package?

A: We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe tranportation. We have exported to 180 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

8. Contact us

Perfect Laser Co., Ltd. (China)

Contact: Ms.Lydia / Sales Department

Add: HengRuichuangzhi Technology Park, No.13 YangQiaohu Road, Jiangxia District, Optical Village, Hubei, China(430200).